AUTOTIVE SOLUTION

홈 > 제품소개 > Automotive Solution

Small camera modules installed in self-driving cars, etc are gradually miniaturized and highly pixelated.

We provide Various inspection facilities such as Focus / Active Align / Calibration / Final test etc, and we are performing our role as the total solution provider with manufacturing our camera module and our inspection facilities.

We provide Various inspection facilities such as Focus / Active Align / Calibration / Final test etc, and we are performing our role as the total solution provider with manufacturing our camera module and our inspection facilities.

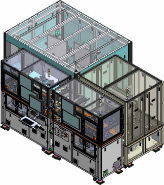

Inline or Auto Machine

-

- Inline Camera Test

- Since there are many errors caused by the operator during the production of Module Camera, this is an Inline tester equipment that can apply all inspections to auto except input and discharge to minimize operator errors. Also, its strength is that the facility is designed and manufactured for accomplishing model’s mixed-producing without the need for model replacement.

- MORE

-

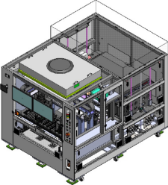

- 2D Calibration & Image test with Handler

- Camera images are obtained by projecting points in three-dimensional space onto a two-dimensional image plane, so there can be a difference between what we see with our naked eyes and the results of camera photography. But if what we see with our naked eyes and the results taken with the camera are different, we will doubt the basic performance of the camera. This is the very reason why you need a Calibration facility that adjusts the target to the standard. The distortion of the camera can be compensated by adjusting internal parameters (such as focal length, principal point, and skew coefficient, etc) and external parameters (such as rotational and parallel transformation between coordinate systems, etc).

- MORE

-

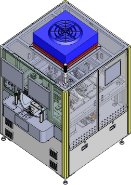

- 2D Calibration with Handler

- Camera images are obtained by projecting points in three-dimensional space onto a two-dimensional image plane, so there can be a difference between what we see with our naked eyes and the results of camera photography. But if what we see with our naked eyes and the results taken with the camera are different, we will doubt the basic performance of the camera. This is the very reason why you need a Calibration facility that adjusts the target to the standard. The distortion of the camera can be compensated by adjusting internal parameters (such as focal length, principal point, and skew coefficient, etc) and external parameters (such as rotational and parallel transformation between coordinate systems, etc).

- MORE

-

- Active Align (Lens & PCB Align)

- Since the smaller the camera module, the more sensitive the relative arrangement of the lens module and the image sensor module, the very small misalignment between the two modules causes the performance of the ultra-small camera module to be significantly reduced. This is why alignments are more important when camera modules are smaller. Luritech’s Active alignment is divided into camera module lens AA and PCB camera module AA, and it is very sophisticated in aligning the image sensor and the optical axis so that the image sensor and lens focus are exactly the same. With our own specialized technology, we Luritech develops and manufactures customizing alignment facilities for various targets such as dual/triple camera modules.

- MORE

-

- Focus & OC & Screw Adjust

- The use of automation facilities has become general because not only is it less accurate to manually adjust the lens focus of camera modules, but also the cost burden is considerable. Focusing facility precisely adjusts the lens’focus to obtain the clearest image by maintaining a constant gap between the image sensor and the lens, and determines abnormalities through focus adjustment and related performance checks of the camera module. Even with the same composition, there is a huge difference in speed and precision, and Luritech is applying long-established technical skills and know-how to adjust the position of the lens and the criteria for determining the accuracy of the focus adjustment results.

- MORE

-

- Lens Inspection

- The final inspection of Lens finished product or import inspection of Module among the parts of the camera module is based on SFR inspection to ensure the resolution of the image when the Lens is settled in the module. Luritech has a final inspection Algorithm from a number of electric part camera modules and Set manufacturers, creating an infrastructure that can match the required resolution criteria.

- MORE

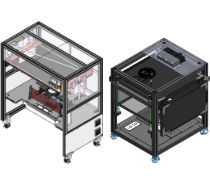

Arrange or Manual Machine

-

- Image Test

- Extremely fine defects from producing/manufacturing Compact camera modules have a significant impact on the performance of the finished product. Luritech’s Final test facility can conduct foreign substance detection and resolution inspection of lens & image sensor for product completeness, and has the know-how to design and manufacture facilities at angle of view (collision/wide angle).

- MORE

-

- Wide angle camera Inspection

- Extremely fine defects from producing/manufacturing Compact camera modules have a significant impact on the performance of the finished product. Luritech’s Final test facility can conduct foreign substance detection and resolution inspection of lens & image sensor for product completeness, and has the know-how to design and manufacture facilities at angle of view (collision/wide angle).

- MORE

-

- Focus & Optical center

- The optical axis between the lens of the camera module and the image sensor must exist within a certain deviation so that there is no shift or rotation of the image. Therefore it is important to adjust the optical axis. Luritech designs and manufactures facilities that can set and adjust optical axis with Manual or Auto using Master Sample.

- MORE

-

- Distortion optical axix

- The optical axis between the lens of the camera module and the image sensor must exist within a certain deviation so that there is no shift or rotation of the image. Therefore it is important to adjust the optical axis. Luritech designs and manufactures facilities that can set and adjust optical axis with Manual or Auto using Master Sample.

- MORE

-

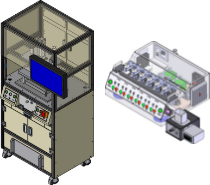

- FCT/ICT Inspection

- Insert the Sensor Drive Init mode, Voltage/Current Check, Eprom Check, FW & Binary Downloading etc. required for Image sensor PCB of the Camera Module so that the Image sensor can deliver the image normally. With our specialized technology, Luritech can apply up to 25Ch simultaneously with a single product or array, and has the strength to add image inspection function.

- MORE

-

- Multi Downloading Inspection

- Insert the Sensor Drive Init mode, Voltage/Current Check, Eprom Check, FW & Binary Downloading etc. required for Image sensor PCB of the Camera Module so that the Image sensor can deliver the image normally. With our specialized technology, Luritech can apply up to 25Ch simultaneously with a single product or array, and has the strength to add image inspection function.

- MORE

-

- Aging Monitoring test

- Nowadays, camera’s ability in adapting the environment is highly evaluated, so we establish a real-time monitoring system for the normal operation of the camera (voltage/current and image output evaluation) at high temperatures and evaluate it before the final examination. Luritech has the strength of designing and manufacturing facilities because it has been working to optimize the evaluation system by building them for many years and applying them to the manufacturing line.

- MORE

-

- ECU Inspection

- ECU, the CPU role of the computer responsible for controlling the electronic devices in the vehicle, including the camera, is a very important component. It is an inspection facility for functional inspection that can control multiple cameras simultaneously with these ECU, and we possess the know-how to design and manufacture the equipment.

- MORE

English

English 한국어

한국어